Integrated Project Delivery: The New Normal

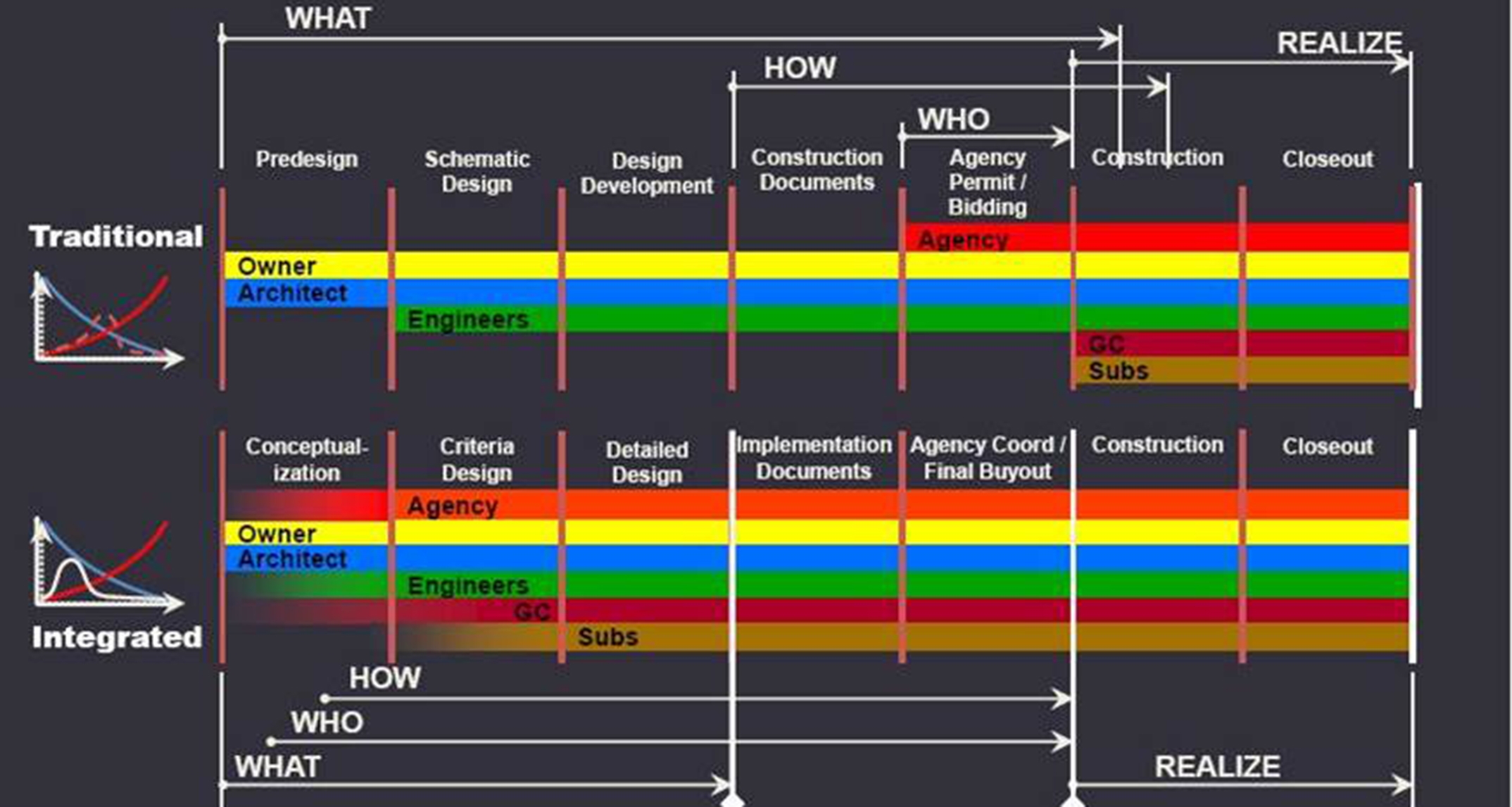

Integrated Project Delivery (IPD) has become an increasingly popular project delivery method, gaining particular momentum in the healthcare industry. But what happens when you take IPD and combine it with Lean construction principles? You get a team-based environment that allows individuals to collaborate from the beginning of design to building occupancy, working together to deliver the highest value while eliminating waste and inefficiencies.

Lean Construction Institute Conference

Healthcare facility owners are recognizing the benefits of a team-based approach to design and construction, where the wide range of knowledge from team members allows for an optimal solution to any given set of decisions. Recently, Jeani Natwick and Jill Kurtz, two of NAC’s senior healthcare designers, attended the Lean Construction Institute’s 18th Annual Congress in Chicago, where they explored the benefits and implications of IPD using Lean tools and processes as a delivery model. Following are five key takeaways from this year’s conference.

Lean Construction Institute Conference

- IPD using Lean tools and processes is becoming a preferred project delivery model for healthcare providers. Owners are beginning to recognize that IPD using Lean tools and processes can produce the best outcomes by utilizing all stakeholders, design professionals and trade partners in the process of facility design and implementation. The process serves to ‘de-silo’ the players and creates a team environment that can expedite decision making and lead to innovation while taking on less risk. With the uncertainty surrounding the future of the Affordable Care Act, using IPD with Lean tools and processes to reduce costs is even more important.

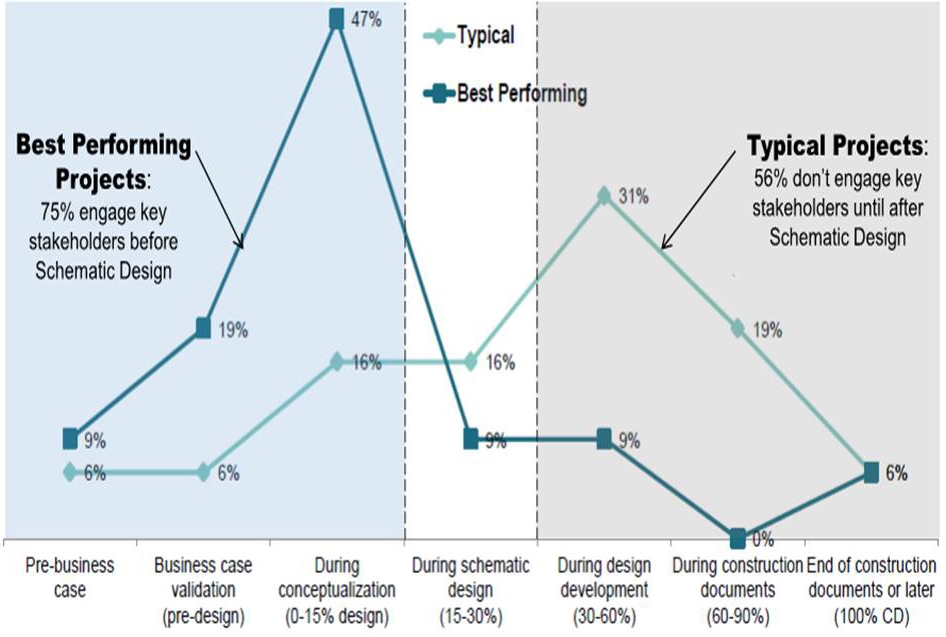

- Lean is a way of thinking and acting to create an environment where all stakeholders have an equal and vested interest. A Lean philosophy recognizes that any successful project undertaking involves collaboration and cooperation between all team members. Key participants are involved from the earliest stages of design and are mandated with planning and developing processes that increase value and eliminate waste.

- An integrated Lean process drives design and construction innovation. Innovation is stimulated when ideas are freely exchanged to address project constraints among all stakeholders. IPD using Lean tools and processes establishes mutual respect and trust because participants are committed to working as a team in the best interest of the project. Particularly in an integrated Lean process, ideas are judged on their merit rather than the individual’s role or status.

- A Big Room workshop engenders collaboration, trust, and transparency. Establishing a project Big Room enables cross-collaboration teamwork, allowing each team member to immediately understand the impact their decisions will have across all healthcare disciplines. A Big Room is more than just a physical space, it is a collaborative behavior that emphasizes transparency during decision making and further builds trust between participants while making process improvements.

- A ‘Last Planner System’ ensures commitments are met.This project planning system manages the discussions, decisions, and commitments between all team members in order to improve predictability and productivity and document delivery speed and savings. It also improves project flow by helping identify and resolve building issues early in the design phase, before they become expensive and time consuming problems on-site.

IPD using Lean tools and processes is a delivery system that seeks to align interests, objectives and practices through a team-based approach. When applied to healthcare projects, it allows design professionals to create and innovate in an engaging environment to select the best combination of facility designs while increasing design process efficiency and lowering costs.